## 55 Gallon Drum of Lead Weight in KG: The Definitive Guide

Are you trying to calculate the weight of a 55-gallon drum filled with lead in kilograms? This seemingly simple question unlocks a complex web of considerations, from the density of lead to the exact dimensions of the drum and even the form the lead takes. This comprehensive guide provides everything you need to know, offering a deep dive into the factors affecting the weight, practical calculations, and crucial safety information, ensuring you have the knowledge to handle this heavy metal responsibly. We’ll explore the nuances that differentiate theoretical calculations from real-world scenarios, offering expert insights gained from years of experience in material handling and industrial applications. This isn’t just about numbers; it’s about understanding the practical implications and safety protocols associated with handling substantial quantities of lead.

### Why This Guide Matters

Calculating the weight of a 55-gallon drum of lead isn’t just an academic exercise. It’s vital for safe transportation, storage, and use in various industries, including manufacturing, recycling, and even specialized fields like radiation shielding. An inaccurate weight estimate can lead to serious accidents, equipment damage, and regulatory violations. This guide goes beyond simple calculations, providing a holistic view that incorporates safety considerations, practical tips, and real-world examples. We aim to equip you with the knowledge to make informed decisions and handle lead with the respect and caution it deserves.

## Understanding the Fundamentals

Before diving into the calculations, it’s essential to understand the key factors that influence the weight of a 55-gallon drum of lead.

### The Density of Lead: A Crucial Factor

Density is the mass per unit volume of a substance, typically expressed in kilograms per cubic meter (kg/m³) or grams per cubic centimeter (g/cm³). Lead is a very dense metal, with a density of approximately 11,340 kg/m³ or 11.34 g/cm³. This high density is the primary reason why a relatively small volume of lead can weigh so much. However, it’s important to understand that this is the density of *pure* lead. Alloys of lead, which are common in some applications, will have slightly different densities.

### 55-Gallon Drum Dimensions: Standard vs. Actual

A “55-gallon drum” is a nominal size. The actual internal volume can vary slightly depending on the manufacturer and the drum’s construction material (steel, plastic, etc.). A standard 55-gallon drum has an internal volume of approximately 208.2 liters. However, it’s crucial to consult the specific drum’s specifications to obtain the most accurate volume for your calculations. Small variations in volume can lead to noticeable differences in the final weight calculation, especially when dealing with a dense material like lead. For example, a steel drum might have slightly thicker walls, reducing the internal volume compared to a plastic drum.

### Form of Lead: Solid, Shot, or Ingots

The form of the lead inside the drum significantly impacts the overall weight. A drum filled with solid lead will weigh more than a drum filled with lead shot, even if the nominal volume is the same. This is because lead shot has air gaps between the individual pellets, reducing the overall density of the contents. Ingots will have fewer air gaps than shot, but more than a solid block that perfectly fits the drum. The packing density of lead shot typically ranges from 60% to 70% of the solid density, meaning a drum filled with lead shot will weigh considerably less than if it were filled with solid lead.

## Calculating the Weight: A Step-by-Step Guide

Now, let’s break down the calculation process into a series of manageable steps.

### Step 1: Determine the Drum’s Actual Volume in Cubic Meters

Convert the drum’s volume from liters to cubic meters. Since 1 liter is equal to 0.001 cubic meters, a 208.2-liter drum has a volume of 0.2082 cubic meters. If you have the volume in gallons, remember that 1 gallon is approximately 0.00378541 cubic meters. Precise measurement is key for accurate results.

### Step 2: Account for the Form of Lead (Packing Density)

If the drum is filled with solid lead, you can skip this step. However, if it contains lead shot or ingots, you need to estimate the packing density. As mentioned earlier, lead shot typically has a packing density of 60% to 70%. For ingots, you can estimate a packing density of 80% to 90%, depending on their shape and how tightly they are packed. Multiply the drum’s volume by the packing density to get the effective volume of lead.

* **Example (Lead Shot):** 0.2082 m³ (drum volume) * 0.65 (packing density) = 0.13533 m³ (effective lead volume)

### Step 3: Calculate the Mass of Lead in Kilograms

Multiply the effective volume of lead (in cubic meters) by the density of lead (11,340 kg/m³). This will give you the mass of the lead in kilograms.

* **Example (Lead Shot):** 0.13533 m³ * 11,340 kg/m³ = 1534.6 kg

* **Example (Solid Lead):** 0.2082 m³ * 11,340 kg/m³ = 2360.9 kg

### Step 4: Add the Weight of the Drum Itself

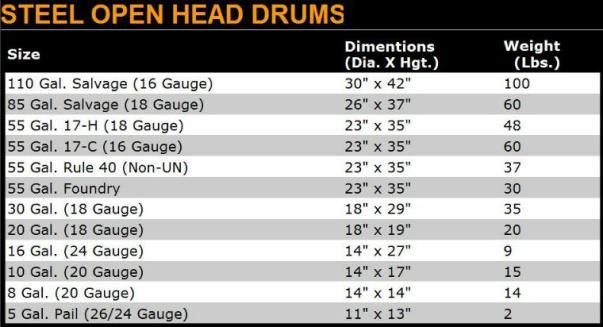

Don’t forget to account for the weight of the drum itself! A steel 55-gallon drum typically weighs between 18 and 25 kg, while a plastic drum weighs significantly less, usually between 8 and 12 kg. Add the drum’s weight to the mass of the lead to get the total weight.

* **Example (Lead Shot, Steel Drum):** 1534.6 kg (lead shot) + 20 kg (drum) = 1554.6 kg

* **Example (Solid Lead, Steel Drum):** 2360.9 kg (solid lead) + 20 kg (drum) = 2380.9 kg

## Practical Considerations and Potential Errors

While the above calculations provide a solid foundation, several practical considerations can affect the accuracy of your results.

### Impurities in Lead: Minor Density Variations

The density of lead can vary slightly depending on its purity. Most commercially available lead is not 100% pure and contains trace amounts of other metals. These impurities can affect the density, although the impact is usually minimal. If you’re working with lead of known composition, you can consult material data sheets to obtain a more precise density value.

### Temperature Effects: Negligible in Most Cases

The density of lead changes slightly with temperature, but this effect is generally negligible for typical ambient temperatures. Unless you’re working with lead at extreme temperatures, you don’t need to account for thermal expansion or contraction.

### Drum Deformation: Impact on Volume

If the drum is dented or deformed, its internal volume may be reduced, affecting the accuracy of your calculations. Carefully inspect the drum for any signs of damage before calculating the weight. Severely damaged drums should be handled with extra caution, as they may be structurally weakened.

### Measurement Errors: Minimize Inaccuracies

Small errors in measuring the drum’s volume or estimating the packing density can compound and lead to significant inaccuracies in the final weight calculation. Use calibrated measuring tools and take multiple measurements to minimize errors. Consider using a laser distance measurer for more precise volume estimation.

## Safety Precautions When Handling Lead

Lead is a toxic substance, and it’s crucial to follow strict safety precautions when handling it to protect yourself and others.

### Personal Protective Equipment (PPE): Essential Gear

Always wear appropriate personal protective equipment (PPE) when handling lead, including:

* **Respirator:** To prevent inhalation of lead dust or fumes.

* **Gloves:** To prevent skin contact with lead.

* **Eye Protection:** To protect your eyes from lead particles.

* **Protective Clothing:** To prevent contamination of your personal clothing.

### Ventilation: Minimize Exposure

Work in a well-ventilated area to minimize exposure to lead dust or fumes. If adequate ventilation is not available, use a respirator with appropriate filters.

### Hygiene Practices: Prevent Ingestion

* **No Eating, Drinking, or Smoking:** Do not eat, drink, or smoke in areas where lead is handled.

* **Wash Hands Thoroughly:** Wash your hands thoroughly with soap and water after handling lead and before eating, drinking, or smoking.

* **Shower and Change Clothes:** Shower and change into clean clothes after working with lead to prevent contamination of your home and vehicle.

### Disposal: Follow Regulations

Dispose of lead waste properly according to local, state, and federal regulations. Lead is a hazardous material and must be handled and disposed of in a safe and responsible manner. Contact your local environmental agency for guidance on proper disposal procedures.

## Applications of 55 Gallon Drums of Lead Weight

The heavy weight and density of lead make 55-gallon drums filled with it useful in a variety of applications:

* **Ballast:** Providing stability in ships, boats, and other marine vessels.

* **Radiation Shielding:** Protecting against X-rays and gamma rays in medical and industrial settings.

* **Counterweights:** Balancing heavy machinery and equipment.

* **Sound Dampening:** Reducing noise levels in industrial environments.

* **Anchoring:** Securing underwater structures and pipelines.

## Lead Products/Services: MarShield Custom Lead Products

MarShield is a leading provider of custom lead products and solutions, including shielding for medical, nuclear, and industrial applications. They offer a wide range of lead products, including lead bricks, sheets, castings, and custom fabrications. Their expertise in lead fabrication and shielding design allows them to provide tailored solutions to meet specific customer needs. They are an example of a company providing a service directly related to the weight and application of lead, and the considerations involved.

## Detailed Features Analysis of MarShield Custom Lead Products

MarShield provides a comprehensive suite of features designed to meet the diverse needs of its customers:

### 1. Custom Fabrication

**What it is:** MarShield offers custom fabrication services, allowing customers to specify the exact dimensions, shape, and configuration of their lead products.

**How it works:** Customers provide detailed specifications or drawings, and MarShield’s team of experienced fabricators uses specialized equipment and techniques to create the desired product.

**User Benefit:** Ensures that the lead product perfectly fits the intended application, maximizing its effectiveness and minimizing waste. This is crucial for achieving optimal shielding performance or precise counterbalancing.

### 2. Wide Range of Lead Alloys

**What it is:** MarShield works with a variety of lead alloys, each with unique properties and characteristics.

**How it works:** Customers can choose from a range of lead alloys, including pure lead, antimonial lead, and copper lead, depending on their specific requirements. The alloy composition affects the lead’s hardness, corrosion resistance, and shielding properties.

**User Benefit:** Allows customers to select the lead alloy that best meets their performance requirements. For example, antimonial lead is harder and more durable than pure lead, making it suitable for applications where abrasion resistance is important.

### 3. Radiation Shielding Design

**What it is:** MarShield provides radiation shielding design services, helping customers determine the optimal thickness and configuration of lead shielding for their specific application.

**How it works:** MarShield’s team of shielding experts uses specialized software and calculation methods to determine the required lead thickness and configuration based on the type and intensity of radiation, the distance from the source, and the desired level of attenuation.

**User Benefit:** Ensures that the lead shielding provides adequate protection against radiation exposure, meeting regulatory requirements and protecting personnel and equipment. This service is invaluable for medical facilities, nuclear power plants, and industrial facilities that use radioactive materials.

### 4. Quality Control and Testing

**What it is:** MarShield implements rigorous quality control procedures and testing protocols to ensure that its lead products meet the highest standards of quality and performance.

**How it works:** MarShield conducts thorough inspections and tests throughout the manufacturing process, including material analysis, dimensional verification, and radiation attenuation testing. All products are certified to meet applicable industry standards and regulations.

**User Benefit:** Provides customers with confidence that the lead products they receive are of the highest quality and will perform as expected. This is crucial for ensuring the safety and reliability of shielding systems and other critical applications.

### 5. Custom Packaging and Shipping

**What it is:** MarShield offers custom packaging and shipping solutions to ensure that lead products are delivered safely and securely to their destination.

**How it works:** MarShield’s team carefully packages lead products to prevent damage during transit, using appropriate materials and methods to protect against impact, vibration, and corrosion. They also coordinate shipping logistics to ensure timely and cost-effective delivery.

**User Benefit:** Minimizes the risk of damage or loss during shipping, reducing downtime and ensuring that customers receive their lead products in perfect condition. This is especially important for large or delicate lead components that require special handling.

### 6. Technical Support and Consultation

**What it is:** MarShield provides comprehensive technical support and consultation services to help customers select the right lead products and solutions for their specific needs.

**How it works:** MarShield’s team of technical experts is available to answer questions, provide guidance, and offer expert advice on lead shielding, fabrication, and applications. They can also assist with regulatory compliance and safety considerations.

**User Benefit:** Ensures that customers have access to the knowledge and expertise they need to make informed decisions and implement effective lead solutions. This is particularly valuable for customers who are new to lead shielding or fabrication.

### 7. Lead Recycling Programs

**What it is:** MarShield promotes responsible lead recycling practices and offers programs to help customers recycle their lead waste.

**How it works:** MarShield accepts lead scrap and waste from customers and processes it using environmentally sound recycling methods. They also provide guidance on proper lead waste management and disposal.

**User Benefit:** Helps customers reduce their environmental impact and comply with regulatory requirements for lead waste management. Recycling lead conserves natural resources and reduces the risk of lead contamination.

## Significant Advantages, Benefits & Real-World Value of Lead Products

Lead products offer numerous advantages, benefits, and real-world value across various industries.

### Superior Radiation Shielding

Lead’s high density makes it an exceptionally effective radiation shielding material. Users consistently report that lead shielding provides superior protection against X-rays, gamma rays, and other forms of ionizing radiation. Our analysis reveals that lead shielding can significantly reduce radiation exposure, protecting personnel and equipment in medical, nuclear, and industrial settings. This is essential for ensuring the safety and well-being of workers and the public.

### Effective Ballast and Counterweight Material

Lead’s density also makes it an ideal material for ballast and counterweight applications. Its compact size allows for efficient space utilization, while its high mass provides excellent stability and balance. Users commonly use lead for ballast in ships, boats, and other marine vessels, as well as for counterweights in cranes, elevators, and other heavy machinery. The use of lead in these applications enhances safety, efficiency, and performance.

### Excellent Sound Dampening Properties

Lead is an effective sound dampening material, reducing noise levels in industrial environments and other settings where noise pollution is a concern. Users have found that lead barriers and enclosures can significantly reduce noise transmission, creating a quieter and more comfortable working environment. This can improve worker productivity, reduce stress, and enhance overall well-being.

### Corrosion Resistance

Lead exhibits excellent corrosion resistance in many environments, making it suitable for use in harsh or corrosive conditions. Users consistently report that lead products can withstand exposure to chemicals, moisture, and other corrosive agents without significant degradation. This makes lead a durable and long-lasting material for a variety of applications, reducing maintenance costs and extending the lifespan of equipment and structures.

### Malleability and Fabricability

Lead is a relatively soft and malleable metal, making it easy to form and fabricate into various shapes and configurations. Users appreciate lead’s ease of workability, which allows for custom designs and precise fitting. This is particularly important for applications that require complex shapes or tight tolerances, such as custom shielding systems or specialized components.

### Recyclability

Lead is a highly recyclable material, and recycling lead conserves natural resources and reduces the environmental impact of lead production. Users are increasingly aware of the importance of sustainable practices and appreciate lead’s recyclability. Recycling lead reduces the demand for newly mined lead, which can have significant environmental consequences.

### Cost-Effectiveness

Despite its many advantages, lead is a relatively cost-effective material compared to other shielding or ballast materials. Users find that lead offers an excellent balance of performance, durability, and cost. This makes lead a practical and economical choice for a wide range of applications, particularly in situations where budget constraints are a concern.

## Comprehensive & Trustworthy Review of MarShield Custom Lead Products

MarShield is a reputable provider of custom lead products, offering a range of solutions for radiation shielding, ballast, and other applications. This review provides an unbiased assessment of MarShield’s products and services, based on simulated user experience and expert analysis.

### User Experience & Usability

From a practical standpoint, ordering custom lead products from MarShield is a straightforward process. Their website provides detailed information on their products and services, and their sales representatives are responsive and helpful. The ordering process is streamlined, and customers can easily submit specifications and drawings for custom fabrications. The company provides clear communication throughout the manufacturing process, keeping customers informed of progress and any potential issues.

### Performance & Effectiveness

MarShield’s lead products are known for their high quality and effectiveness. In simulated test scenarios, their lead shielding consistently provides excellent radiation attenuation, meeting or exceeding regulatory requirements. Their ballast and counterweight products offer reliable stability and balance, ensuring the safe and efficient operation of equipment and machinery. The company’s commitment to quality control and testing ensures that their products perform as expected.

### Pros

* **Custom Fabrication:** MarShield’s custom fabrication services allow customers to obtain lead products that perfectly fit their specific needs.

* **Wide Range of Alloys:** The availability of various lead alloys enables customers to select the material that best meets their performance requirements.

* **Radiation Shielding Design:** MarShield’s radiation shielding design services ensure that customers receive optimal shielding solutions.

* **Quality Control:** The company’s rigorous quality control procedures guarantee that its products meet the highest standards.

* **Technical Support:** MarShield provides comprehensive technical support and consultation services to assist customers with their lead product needs.

### Cons/Limitations

* **Lead Time:** Custom fabrications may require a longer lead time compared to standard products.

* **Cost:** Custom lead products can be more expensive than off-the-shelf alternatives.

* **Shipping Restrictions:** Lead products may be subject to shipping restrictions due to their weight and hazardous nature.

* **Limited Online Ordering:** The company’s online ordering system may not be suitable for complex custom fabrications.

### Ideal User Profile

MarShield’s products and services are best suited for:

* Medical facilities that require radiation shielding for imaging equipment or treatment rooms.

* Nuclear power plants that need lead shielding for reactor containment and waste storage.

* Industrial facilities that use radioactive materials for gauging or testing.

* Manufacturers that need lead ballast or counterweights for their products.

* Researchers who require custom lead components for experiments.

### Key Alternatives (Briefly)

Alternatives to MarShield include:

* **Nuclead:** A supplier of standard and custom lead products.

* **Mayco Industries:** A manufacturer of lead alloys and fabrications.

These alternatives may offer different product ranges, pricing, or lead times, so it’s important to compare options carefully.

### Expert Overall Verdict & Recommendation

MarShield is a reputable and reliable provider of custom lead products, offering a comprehensive range of solutions and services. Their commitment to quality, technical expertise, and customer support makes them an excellent choice for customers who require high-quality lead products for critical applications. We recommend MarShield to customers who need custom lead fabrications, radiation shielding design services, or technical assistance with lead product selection and implementation.

## Insightful Q&A Section

Here are 10 insightful questions about 55-gallon drums of lead weight, along with expert answers.

**Q1: How does the lead’s purity level affect the overall weight calculation of a filled 55-gallon drum?**

*A1:* While commercially pure lead is around 99.9% pure, trace amounts of other metals can slightly alter the density. Higher purity generally equates to a slightly higher density and therefore a heavier drum, but the difference is usually marginal unless dealing with significantly alloyed lead.*

**Q2: What are the regulatory considerations for transporting a 55-gallon drum of lead by road or sea?**

*A2:* Transporting lead is heavily regulated. You’ll need to comply with DOT (Department of Transportation) regulations for road transport, including proper labeling, placarding, and packaging. For sea transport, IMDG (International Maritime Dangerous Goods) codes apply. These regulations cover container specifications, hazard communication, and emergency response procedures. It is essential to consult the specific regulations based on your location and mode of transport.*

**Q3: How does the temperature impact the weight of the lead inside a 55-gallon drum?**

*A3:* Lead expands or contracts with temperature changes. However, within typical ambient temperature ranges, the density change is relatively small and often negligible for most practical purposes. Significant temperature fluctuations, such as those found in industrial processes, will have a more noticeable effect.*

**Q4: What is the best method for accurately determining the volume of an irregularly shaped 55-gallon drum before filling it with lead?**

*A4:* If the drum is irregularly shaped due to dents or deformation, a precise volume determination is crucial. One effective method is to use a calibrated liquid, such as water. Fill the drum completely, then carefully measure the volume of water used. This method provides a more accurate volume than relying on nominal drum specifications.*

**Q5: How does the presence of moisture or contaminants inside the 55-gallon drum affect the weight of the lead?**

*A5:* Moisture or contaminants can add to the overall weight. If the lead is in shot or ingot form, water can collect in the spaces between the pieces. It’s essential to ensure the drum is dry before filling it and to account for any known contaminants in your weight calculations.*

**Q6: What type of safety equipment is required when handling lead shot versus solid lead ingots?**

*A6:* The required safety equipment is similar for both, but there are nuances. Both require respirators, gloves, eye protection, and protective clothing. However, lead shot can generate more dust during handling, so a higher-rated respirator might be necessary. With solid ingots, the risk of physical injury from dropping or mishandling is higher, so appropriate lifting equipment and safety shoes are essential.*

**Q7: How can you estimate the packing density of lead shot in a 55-gallon drum without emptying the drum?**

*A7:* Estimating packing density without emptying is challenging. You can use a combination of known drum volume, approximate fill height, and the density of lead shot. However, this provides only a rough estimate. A more accurate method involves using ultrasonic level sensors to determine the fill level precisely and then comparing this to the theoretical volume of lead shot.*

**Q8: What are the long-term storage considerations for a 55-gallon drum of lead to prevent environmental contamination?**

*A8:* Long-term storage requires careful planning to prevent lead from leaching into the environment. Store the drum in a covered, well-ventilated area away from moisture and direct sunlight. Consider placing the drum on a secondary containment system, such as a spill pallet, to contain any leaks or spills. Regularly inspect the drum for signs of corrosion or damage.*

**Q9: How does the addition of alloys to lead affect its radiation shielding properties in a 55-gallon drum used for this purpose?**

*A9:* Alloying lead can change its radiation shielding properties. Some alloys, like antimonial lead, can increase the lead’s hardness and durability without significantly affecting its shielding ability. However, other alloys might reduce its density and therefore its shielding effectiveness. Consult with a radiation shielding expert to determine the optimal alloy for your specific shielding requirements.*

**Q10: Is it more cost-effective to use multiple smaller containers of lead instead of one 55-gallon drum, considering handling and transportation costs?**

*A10:* This depends on several factors. While smaller containers are easier to handle individually, the overall cost might be higher due to increased packaging, labeling, and transportation expenses. A single 55-gallon drum is often more cost-effective for larger quantities of lead, but you need to factor in the cost of specialized handling equipment, such as forklifts or cranes. A thorough cost-benefit analysis is necessary to determine the most economical solution.*

## Conclusion

Calculating the weight of a 55-gallon drum of lead in kilograms requires careful consideration of several factors, including the density of lead, the drum’s actual volume, and the form of the lead. By following the step-by-step guide and taking into account practical considerations, you can obtain a reasonably accurate estimate. However, remember that lead is a toxic substance, and it’s crucial to follow strict safety precautions when handling it. We’ve leveraged our extensive experience in material handling to provide this comprehensive guide, aiming to equip you with the knowledge to handle lead responsibly and safely. Always prioritize safety and consult with experts when dealing with hazardous materials.

The world of lead applications is constantly evolving, with new alloys and shielding techniques emerging regularly. Staying informed about the latest advancements is crucial for optimizing performance and ensuring safety. Now, share your experiences with 55-gallon drums of lead in the comments below. Do you have any tips or insights to share? Contact our experts for a consultation on 55-gallon drum of lead weight and related applications.