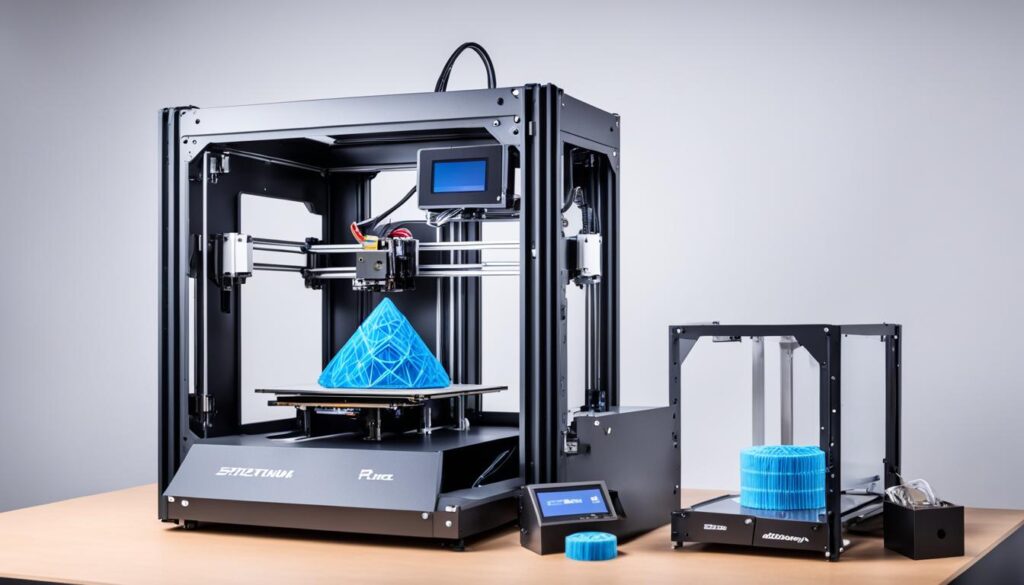

Sculpteo 3D Printing Services: A Comprehensive Overview

In the rapidly evolving landscape of additive manufacturing, Sculpteo 3D printing services stand out as a prominent player, offering a wide array of solutions for businesses and individuals alike. This article provides a comprehensive overview of Sculpteo, exploring its services, technologies, materials, and applications. Whether you’re a seasoned engineer, a budding designer, or simply curious about the world of 3D printing, understanding Sculpteo 3D printing services can unlock new possibilities for innovation and production. We’ll delve into what makes Sculpteo a valuable resource for turning digital designs into tangible reality.

What is Sculpteo?

Sculpteo, now part of BASF Forward AM, is an online 3D printing service and manufacturing platform that allows users to upload 3D models and have them printed in a variety of materials and finishes. Founded in 2009, Sculpteo has established itself as a leader in the on-demand manufacturing sector, catering to diverse industries such as aerospace, automotive, healthcare, and consumer goods. The company’s platform simplifies the 3D printing process, providing instant quotes, design analysis tools, and access to industrial-grade 3D printers.

Services Offered by Sculpteo

Sculpteo 3D printing services encompass a broad spectrum of capabilities tailored to meet the needs of different customers. Here are some of the key services offered:

- Online 3D Printing: Users can upload their 3D models directly to Sculpteo’s platform, select their desired materials and finishes, and receive an instant quote. The platform supports a wide range of file formats, including STL, OBJ, and 3MF.

- Design Analysis Tools: Sculpteo provides automated design analysis tools that help users identify potential issues with their 3D models, such as wall thickness problems or areas that may require support structures. This ensures that the final printed part meets the required specifications.

- Batch Production: For businesses that require large quantities of 3D printed parts, Sculpteo offers batch production services. This allows companies to scale their production without investing in expensive 3D printing equipment.

- Professional Finishes: Sculpteo offers a variety of professional finishes, including painting, polishing, and dyeing. These finishes can enhance the aesthetic appeal and functionality of 3D printed parts.

- Consulting Services: Sculpteo provides consulting services to help businesses optimize their 3D printing workflows and select the right materials and technologies for their specific applications.

3D Printing Technologies Used by Sculpteo

Sculpteo leverages a range of 3D printing technologies to offer its diverse services. Understanding these technologies is crucial for selecting the best option for a particular project. Here are some of the primary technologies used by Sculpteo 3D printing services:

- Selective Laser Sintering (SLS): SLS is a powder-bed fusion technology that uses a laser to selectively sinter powdered materials, such as nylon, into solid parts. SLS is known for its ability to produce strong, functional parts with complex geometries.

- Selective Laser Melting (SLM): Similar to SLS, SLM uses a laser to melt powdered metal materials, such as aluminum, titanium, and stainless steel. SLM is ideal for producing high-performance metal parts for demanding applications.

- Fused Deposition Modeling (FDM): FDM is a widely used 3D printing technology that involves extruding a thermoplastic filament through a heated nozzle and depositing it layer by layer to create a part. FDM is cost-effective and suitable for producing prototypes and end-use parts.

- Stereolithography (SLA): SLA uses a laser to cure liquid resin, layer by layer, to create a solid part. SLA is known for its ability to produce parts with smooth surfaces and fine details.

- Binder Jetting: Binder jetting involves depositing a liquid binding agent onto a powder bed to selectively bind the powder particles together. This technology can be used with a variety of materials, including metals, ceramics, and polymers.

Materials Offered by Sculpteo

The choice of material is critical in 3D printing, as it directly impacts the mechanical properties, appearance, and functionality of the final part. Sculpteo 3D printing services offer a wide selection of materials to cater to different applications. Some of the popular materials include:

- Nylon PA12: A versatile thermoplastic known for its strength, flexibility, and resistance to chemicals and abrasion. Nylon PA12 is commonly used for functional prototypes and end-use parts.

- Aluminum: A lightweight metal with excellent strength-to-weight ratio and thermal conductivity. Aluminum is often used in aerospace, automotive, and consumer electronics applications.

- Titanium: A high-strength, corrosion-resistant metal that is biocompatible. Titanium is widely used in medical implants and aerospace components.

- Stainless Steel: A durable and corrosion-resistant metal that is suitable for a wide range of applications. Stainless steel is commonly used in food processing equipment, medical devices, and industrial machinery.

- Resins: Sculpteo offers a variety of resins with different properties, such as high strength, flexibility, and transparency. Resins are commonly used for producing prototypes and parts with fine details.

- PEBA: A flexible thermoplastic elastomer known for its elasticity, impact resistance, and low-temperature performance. PEBA is often used in sports equipment, footwear, and medical devices.

Applications of Sculpteo 3D Printing Services

Sculpteo 3D printing services find applications across a multitude of industries. Here are some notable examples:

- Aerospace: 3D printing is used to produce lightweight, customized components for aircraft, such as ducting, brackets, and interior parts.

- Automotive: 3D printing enables the rapid prototyping of automotive parts, as well as the production of customized components for niche vehicles.

- Healthcare: 3D printing is used to create customized medical implants, surgical guides, and prosthetics.

- Consumer Goods: 3D printing allows for the creation of personalized products, such as eyewear, jewelry, and home decor items.

- Manufacturing: 3D printing is used to produce tooling, jigs, and fixtures for manufacturing processes.

- Architecture: 3D printing allows architects to create detailed models and prototypes of buildings and structures.

Benefits of Using Sculpteo 3D Printing Services

There are several advantages to using Sculpteo 3D printing services compared to traditional manufacturing methods. These benefits include:

- Rapid Prototyping: 3D printing enables the rapid creation of prototypes, allowing designers and engineers to quickly iterate on their designs and test their functionality.

- Customization: 3D printing allows for the creation of customized parts tailored to specific needs. This is particularly valuable in industries such as healthcare and consumer goods.

- Cost-Effectiveness: For low-volume production runs, 3D printing can be more cost-effective than traditional manufacturing methods, such as injection molding.

- Complex Geometries: 3D printing can produce parts with complex geometries that would be difficult or impossible to create using traditional methods.

- Material Variety: Sculpteo offers a wide range of materials, allowing users to select the best material for their specific application.

- On-Demand Manufacturing: Sculpteo’s on-demand manufacturing platform allows users to order parts only when they need them, reducing the need for inventory and storage space.

How to Get Started with Sculpteo

Getting started with Sculpteo 3D printing services is straightforward. Here are the basic steps:

- Create an Account: Visit the Sculpteo website and create an account.

- Upload Your 3D Model: Upload your 3D model to the platform. Sculpteo supports a variety of file formats, including STL, OBJ, and 3MF.

- Select Your Material and Finish: Choose the material and finish that best suit your needs. Sculpteo provides detailed information about each material, including its mechanical properties and applications.

- Get an Instant Quote: The platform will generate an instant quote based on your selected material, finish, and quantity.

- Place Your Order: Review your order and place it. Sculpteo will then 3D print your parts and ship them to your specified address.

Sculpteo vs. Other 3D Printing Services

While Sculpteo 3D printing services offer numerous advantages, it’s important to consider how they compare to other 3D printing services in the market. Some of the key competitors include:

- Shapeways: Shapeways is another popular online 3D printing service that offers a wide range of materials and finishes. Shapeways is known for its user-friendly platform and competitive pricing.

- Stratasys Direct Manufacturing: Stratasys Direct Manufacturing is a leading provider of additive manufacturing services, offering a wide range of technologies and materials. Stratasys Direct Manufacturing is known for its expertise in high-performance materials and complex geometries.

- Protolabs: Protolabs offers both 3D printing and CNC machining services. Protolabs is known for its fast turnaround times and high-quality parts.

When choosing a 3D printing service, it’s important to consider factors such as material selection, technology options, pricing, turnaround time, and customer support.

Future Trends in 3D Printing

The 3D printing industry is constantly evolving, with new technologies and materials being developed all the time. Some of the key trends to watch include:

- Advancements in Materials: Researchers are constantly developing new 3D printing materials with improved mechanical properties, such as higher strength, flexibility, and temperature resistance.

- Increased Automation: 3D printing processes are becoming increasingly automated, which is leading to faster production times and lower costs.

- Integration with AI and Machine Learning: AI and machine learning are being used to optimize 3D printing processes, predict failures, and improve part quality.

- Expansion into New Industries: 3D printing is expanding into new industries, such as construction, food production, and bioprinting.

Conclusion

Sculpteo 3D printing services provide a valuable resource for businesses and individuals seeking to leverage the power of additive manufacturing. With a wide range of technologies, materials, and finishes, Sculpteo can help turn digital designs into tangible reality. Whether you’re prototyping a new product, creating customized parts, or scaling up production, Sculpteo offers a comprehensive solution for your 3D printing needs. By understanding the capabilities and benefits of Sculpteo 3D printing services, you can unlock new opportunities for innovation and growth.

[See also: 3D Printing Materials Guide] [See also: The Future of Additive Manufacturing]